Medical Surgical Instruments

Welcome to buy Medical Surgical Instruments from us. Every request from customers is being replied within 24 hours.

Send Inquiry

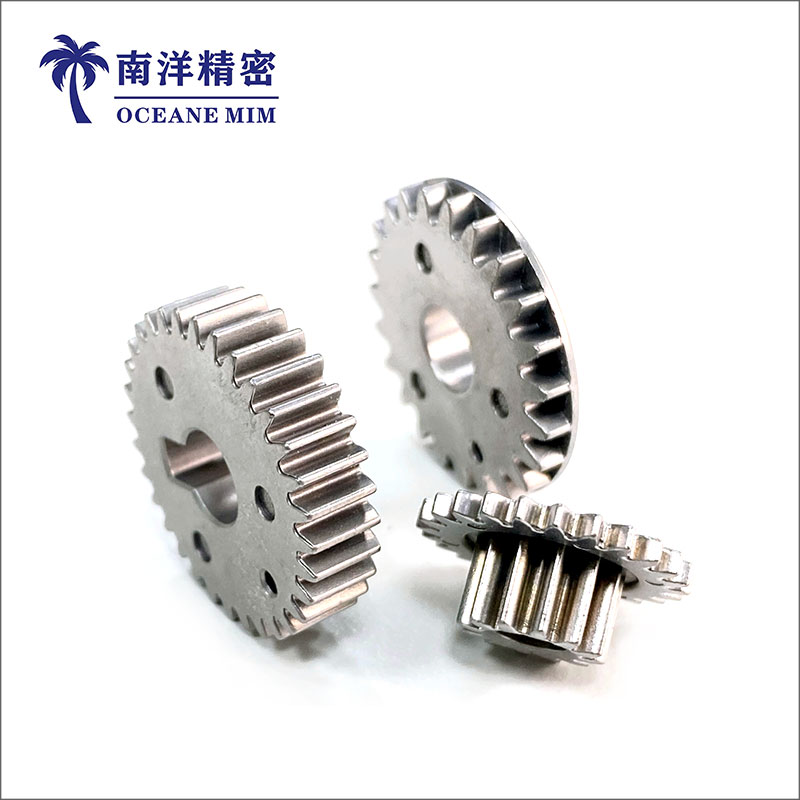

Medical Surgical Instruments

Product Description

endoscope, endoscopic scalpel, rack, scalpel scalpel, medical forceps, endoscopic chamber, peeling electrodes

Metal Injection Molding (MIM) Process

The Metal Injection Molding (MIM) process combines the design flexibility of Plastic Injection Molding with the strength and integrity of wrought metals to offer cost-effective solutions for highly complex part geometries.

The MIM process is typically explained as four unique processing steps (Compounding, Molding, De-binding, and Sintering) to produce a final part.

1.Compounding / Feedstock

The MIM process starts with the compounding or feedstock preparation process. Fine metal powder less than 20µ particle size is blended with thermoplastic and wax binders in precise amounts. The metal powder to binder ratio is approximately 60:40 by volume. The blend is placed in special mixing equipment and heated to a temperature causing the binders to melt. The mass is mechanically mixed until the metal powder particles are uniformly coated with the binders. The mass is cooled and then granulated into free-flowing pellets (feedstock) that will be accepted by the metal injection molding machine.

2. Injection Molding

Injection Molding is identical in equipment and technique to how Plastic Injection Molding takes place. The pelletized feedstock is fed into an injection molding machine where it is heated and injected into a mold cavity under high pressure. The molded part (now termed “green part”) is allowed to cool and then ejected from the mold so the process can repeat. Since only the binders melt (to carry the metal powders), the entire process happens at about 200° C. The tooling can be of multiple cavities for high production rates. The mold cavity is sized approximately 20% larger to compensate for shrinkage that takes place during sintering. The shrinkage change is precisely known for each material.

3. Binder Removal (Debinding) Process

After the Injection Molding, the molded part will move to the next step called Debinding or binder removal process. Binder removal is a process where the binder materials are removed from the molded MIM component. This process is usually done in several steps whereby the majority is removed before the sintering step, leaving behind only enough binder to handle the parts into the sintering furnace. Binder removal can be accomplished by multiple methods, the most popular being solvent extraction. After binder removal, the part is now semi-porous which allows the remaining binder to easily escape during the sintering process.

4. Sintering Process – Sintered Parts

The debind parts are placed on ceramic setters which are loaded into a high temperature, atmosphere-controlled sintering furnace. The brown parts are slowly heated in a protective atmosphere to drive out the remaining binders. Once the binders are evaporated, the metal part is heated to a high temperature where the void space between the particles is eliminated as the particles fuse together. The part shrinks isotropically to its design dimensions and transforms into a dense solid. The sintered part density is typically greater than 97% theoretical for most materials. The high sintered part density gives the product properties that are similar to wrought materials.

5. Finishing / Secondary Processes

Finishing/Machining processes are not part of the Metal Injection Molding Process. Depending upon final requirements, certain finishing/machining operations may be performed to the sintered part. To improve physical properties, heat treatment can be done as on any metal. Any type of machining operation can be performed to achieve Metal Injection Molding (MIM) tolerances that are more precise than what the process can capably supply. Plating and Coatings can be readily applied due to high material density. Numerous mechanical assembly techniques such as welding or cold working can also be successfully used.